Windows on Craft

Yoshiharu Tsukamoto Laboratory (Tokyo Institute of Technology), Window Workology, 2014

Windows and craftspeople act as partners in Japanese workplaces where work is conducted by hand. Windows take part in the manufacturing processes by bringing in or expelling elements of nature, such as light, wind, heat, smoke and steam. The properties of materials such as clay, wood, cloth and paper are transformed around such 'working windows,' and craftspeople hone their sensitivity and skills by acutely sensing these changes through their everyday work.

Windows hence establish links between various things and their behaviors, and in doing so, they enable us to understand the ecologies that surround us.

Indigo-Dyed Fabric / Aizome, Higeta Aizome Kōbō Mashiko, Haga, Tochigi prefecture

Dried Persimmons, Persimmon-Drying Hut in Hata, Matsue, Shimane prefecture

Shoji Hamada Memorial Mashiko Sankōkan Workshop, Mashiko, Haga, Tochigi prefecture

Yuba (soy milk skin), Yubahan, Kyoto, Kyoto prefecture

Izumo Washi

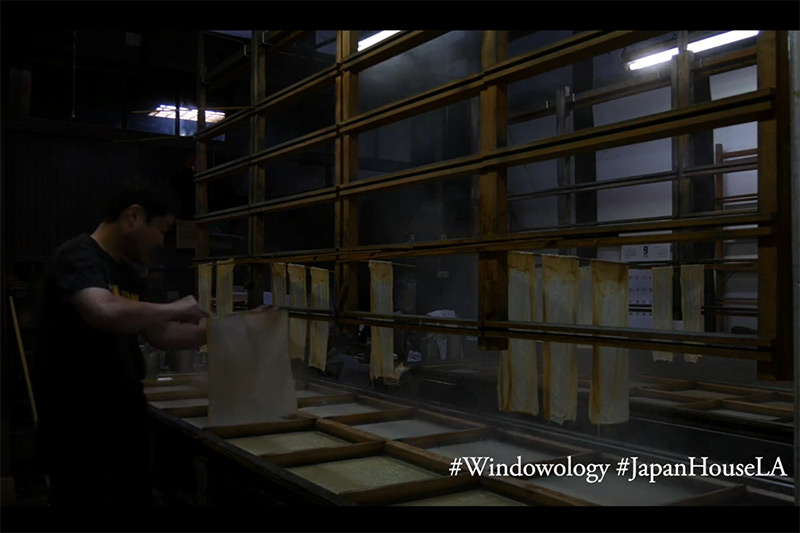

Izumo Washi - Handmade Japanese paper, lzumo Mingeishi Kōbō Drying Room, Matsue, Shimane prefecture

Izumo Mingeishi uses the beautiful movement of water to bring out the characteristics of plant fiber within the paper. Gampi and paper mulberry (kozō) are softened in water overnight before boiled with soda ash until soft. The fibers are washed and beaten to produce the pulp. The pulp is mixed with water and a starchy substance called neri that is extracted from the tororo aoi plant. Once the pulp is poured into a wooden frame to drain, the water is squeezed out and pressed. The moist paper is stretched out to dry on a steam-heated steel plate using a brush. The heat and steam generated during the drying process are discharged from the wooden latticed windows.

Izumo Mingeishi Kōbō was established by Abe Eishiro in 1931 after Abe joined the Mingei Movement (Folk Craft Movement) with Yanagi Sōetsu. Abe was from Shimane prefecture and became a master craftsman of paper making. Abe is well known for receiving Living National Treasure status in 1968.

The Mingei Movement focuses on the overlooked beauty of art and crafts made by average people that are practical and used in daily life.

Salt

Salt, Okinawa Sea Salt Research Institute Graduation Tower, Aguni, Okinawa prefecture, Japan

Seawater is pumped and passed through a 10m high tower like building with walls built from perforated blocks to encourage air circulation. These blocks act as windows to regulate the air flow in the tower. Approximately 15,000 bamboo slats are hung in the tower. Seawater is pumped repeatedly over the bamboo slats and circulated 6 to 7 times to increase the salinity of the solution (to around 20% salt content). This process takes about a week or more.

Two types of salt can be made from this brine depending on the finishing process followed. Open-pan salt (Kamataki shio) production involves boiling the brine in an open metal pan, whereas sun-dried salt (Tenpi shio) relies on solar evaporation. For the sun-dried sea salt, the salt may be dried in a greenhouse under the sun for 20 days during the summer and 60 days during the winter. The crystallized salt is transferred to a stone drainage tank and left to dry naturally. For the open-pan salt, the brine is boiled in a vat for 30 hours. The extracted salt is transferred to a wooden drainage tank and left to dry naturally for 6-18 days. The resulting salts are slightly different in taste and texture, with the sun-dried salt forming larger crystals. Each process depends on the weather (humidity, wind, sunlight, heat). These processes cannot be compromised, and are mass produced in a factory setting according to the research institute guidelines.

Incense Sticks

Incense Sticks, Matsui Senko Seizoten, Toyokawa, Aichi prefecture, Japan

Matsui Senko Seizoten has been making incense sticks since 1916 in Toyokawa, Aichi prefecture. Powdered cedar and sandalwood are mixed with 160-180 degree water and colored dye. The ingredients are kneaded into a paste by machine, shaped into sticks and air dried on stacked shelving for over two weeks. During the drying process, the amount of air is adjusted depending on the humidity using louvered windows.

Smoked Daikon

Smoked Daikon (White Radish), Ogachino Kimuraya, Yuzawa, Akita prefecture, Japan

Smoked Daikon pickles (Iburigakko) are a very important winter dish for people in Akita. Over half of the year the area is covered with snow, with an average annual snowfall of six feet. In the Fall, daikon radishes are harvested. After the daikon are washed, they are strung by hand from the thickest on top to the thinnest on the bottom. The most important and rigorous task is smoking the hanging radishes with smoldering oak logs for four to five days and nights to add aroma. The smoked daikon are then pickled in a mixture of rice bran, salt, and sugar for several months.

Windowlology Exhibition | Gallery Image

©JAPAN HOUSE Los Angeles

Igarashi Tarō on Windows on Craft

'Windowology' research by Yoshiharu Tsukamoto Laboratory sponsored by Window Research Institute, YKK AP Inc.

Explore Next Theme Return to Exhibition Page