Views of Mino

Mino is located in the southern part of Gifu prefecture. Once known as Mino no kuni, or the province of Mino, the region has a long and rich history of ceramics, which have been made in the area since the seventh century. It was in the late sixteenth century, however, that ceramic production began to truly blossom in Mino. At that time, potters from the ancient ceramics center of Seto nearby settled in Mino and started making Kizeto and Setoguro ware (based on earlier Seto stoneware ceramics), as well as Shino and Oribe ware, all ceramics that were highly admired by practitioners of the tea ceremony.

For the next two hundred years, the potters of Mino continued to create wares that skillfully blended a high aesthetic sensibility with functionality, from tea ceremony ceramics to dishes, bowls, and other utilitarian vessels for daily use. In the nineteenth century, Mino potters began using porcelain clay to make housewares, including dishes that were decorated with underglaze cobalt blue designs as well as colorful overglaze enamels. Some of these designs were hand-painted onto the vessels, but the kilns also excelled at various types of printed decoration, including copperplate transfers.

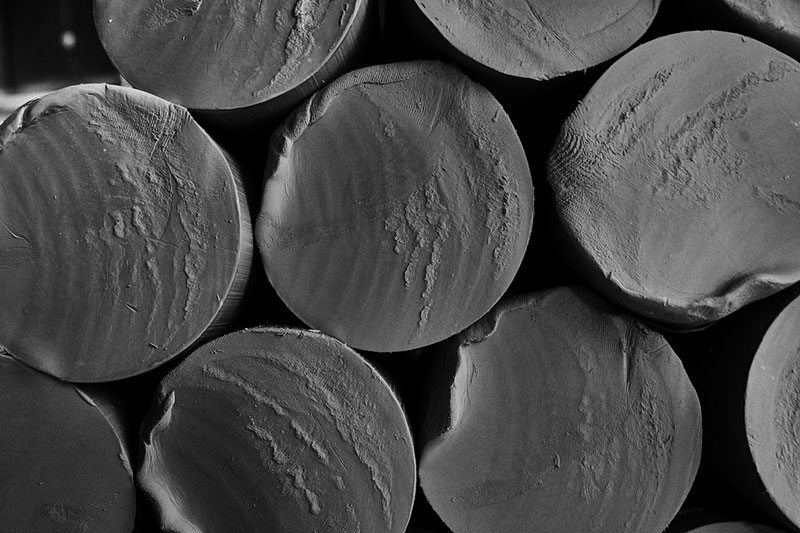

By the mid-twentieth century, improved technology and mass-production techniques enabled Mino to become Japan’s leading ceramics region. Mino currently produces 90 percent of the country’s porcelain ramen bowls. The Ceramic Valley of Mino is known for its ability to innovate and adapt to contemporary needs and now creates many ceramic styles, including fifteen styles listed as traditional regional handicrafts.